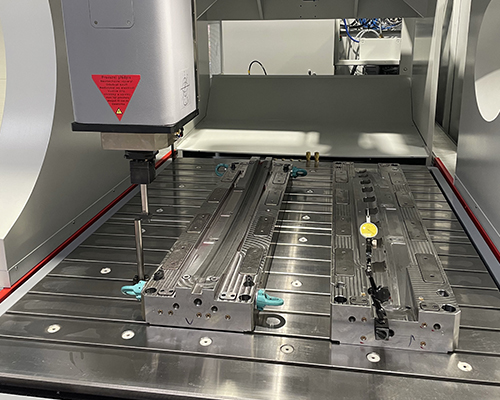

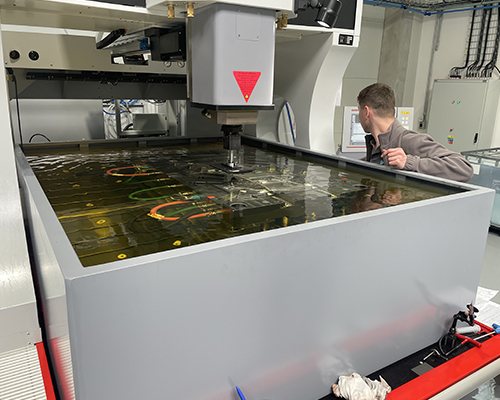

EDM machining

An integral part of injection mould manufacturing is an EDM machining, where material is removed by an electrical discharge between the tool and the surface to be machined. The tool can be shaped electrode (graphite or copper) or a special brass wire (wire cutting).

EDM machining in KOWA, also as a separate service, is thanks to the newly acquired Exeron EDM 316 at high level. This machine can machine parts with a size of up to 1750 x 1350 mm, machine travels are X-1500 mm, Y-1150 mm and Z-750 mm with a maximum part weight of 8 000 kg.